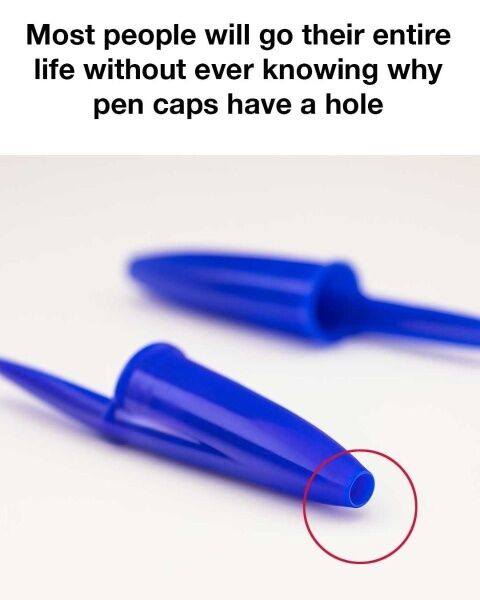

Most people will never know. Full article 👇 💬

At first glance, a pen cap seems like the most basic of objects—just a small piece of plastic meant to protect the writing tip. But if you’ve ever looked closely at one, especially on popular ballpoint pens, you might have noticed something curious: a tiny hole at the top.

It’s easy to assume it’s just a manufacturing quirk or a random design detail. But the reality is much more thoughtful. That little hole is the result of careful engineering and safety design, and it serves multiple important purposes—from potentially saving lives to keeping your pen in better working condition.

Let’s break down exactly why that tiny hole is there, and why it’s more meaningful than you might expect.

1. Safety First: A Lifesaving Feature in Disguise

One of the primary—and perhaps most vital—reasons for the hole in a pen cap is to prevent suffocation.

We’ve all had moments of absentmindedly chewing on a pen cap during a meeting, class, or while working. For children especially, pen caps can be a choking hazard if accidentally swallowed. In fact, in the past, many choking incidents were caused by small plastic objects just like pen caps.

In response, regulatory bodies like the International Organization for Standardization (ISO) introduced safety guidelines for pen manufacturers. Since then, most pen companies, including big names like BIC and Pilot, began adding small holes at the top of their pen caps. The logic is simple yet profound: if someone accidentally swallows a pen cap, the hole allows a small passage of air, giving the person a better chance to breathe until medical help arrives.

It’s not a guaranteed lifesaver in every situation—but it can make the difference between a full blockage and a chance for survival.

2. Pressure Equalization = Better Ink Performance

Beyond safety, the hole plays a technical role in ensuring consistent ink flow.

Inside every pen is a small ink cartridge, often made of soft plastic or metal. As the pen is used, the air pressure inside the pen’s body changes, especially when it’s capped tightly or exposed to temperature variations. These pressure changes can lead to one of two problems: ink leaking out or the flow of ink slowing down or stopping entirely.

The small hole in the cap helps equalize internal and external air pressure when the cap is sealed. This reduces the chance of air getting trapped inside, which could otherwise push ink out or cause the pen to dry up prematurely.

Think of it as a miniature version of a ventilation valve, helping the pen “breathe” and keep working reliably no matter the weather or altitude. It’s the reason why you can take a ballpoint pen on an airplane without it exploding ink all over your shirt pocket.

3. Smart Economics: Cost-Effective Design

While safety and performance are critical, manufacturers also have to think about cost—especially when they’re producing pens by the millions every year.

Surprisingly, that small hole can help reduce material usage. By slightly altering the structure of the cap, the hole helps reduce the amount of plastic required to mold the part. While the difference is tiny on a single pen, when multiplied across global production, the savings become significant—not just in materials, but also in manufacturing time and efficiency.

The hole can also assist in the injection molding process, making it easier for machines to shape the cap cleanly and quickly. In short, it speeds up production, reduces waste, and helps manufacturers keep pen prices low.

So the next time you buy a pen for less than a dollar, remember: that tiny hole helped make it affordable.

4. A Signature Look: Branding and Design Appeal

Designers also use the hole to add a unique touch to the pen’s appearance. While it began as a practical feature, many pen companies now use it as a recognizable element of their product design.

Take BIC’s Cristal pen, for example—one of the most iconic and best-selling pens in the world. The small hole in the cap has become part of its identity, to the point that many people associate that feature with the BIC brand itself. It’s become a visual cue for authenticity, helping consumers recognize the real product from knockoffs.

Some premium pen makers even use the hole as an opportunity for creativity, shaping it in a distinctive way or combining it with the brand’s logo. It’s proof that even a functional detail can serve aesthetic and branding purposes in the right hands.

5. A Humble Reminder of Thoughtful Design

Ultimately, the tiny hole in a pen cap is an example of how good design often goes unnoticed—until you stop and look.

It’s easy to assume simple objects are exactly that: simple. But when you consider all the people involved in making sure a pen is safe, functional, cost-effective, and stylish, you realize that even the smallest features are the result of intentional, thoughtful design.

Engineers, designers, safety experts, and manufacturers all play a role in turning what appears to be a throwaway object into something quietly brilliant.

Next Time You See a Pen Cap…

Pause for a second. Turn it over in your hand. Look at that little hole not as a flaw or oddity—but as a symbol of how design can solve multiple problems at once: saving lives, improving performance, reducing costs, and building identity.

The pen cap hole may be small, but the thinking behind it is anything but.

So the next time you reach for a pen and notice that tiny hole, you’ll know—it’s not just a random quirk. It’s smart, multifunctional engineering hiding in plain sight.